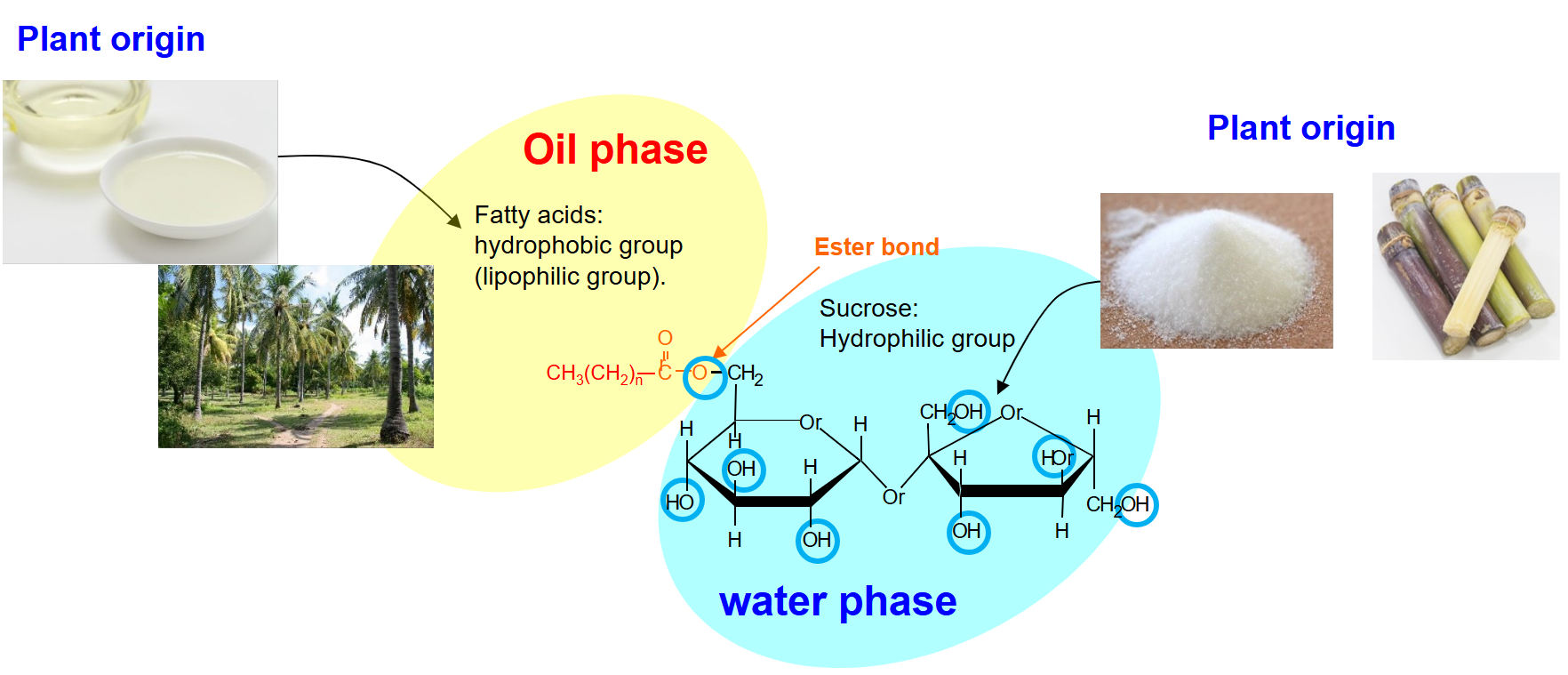

Structure of Sugar Esters

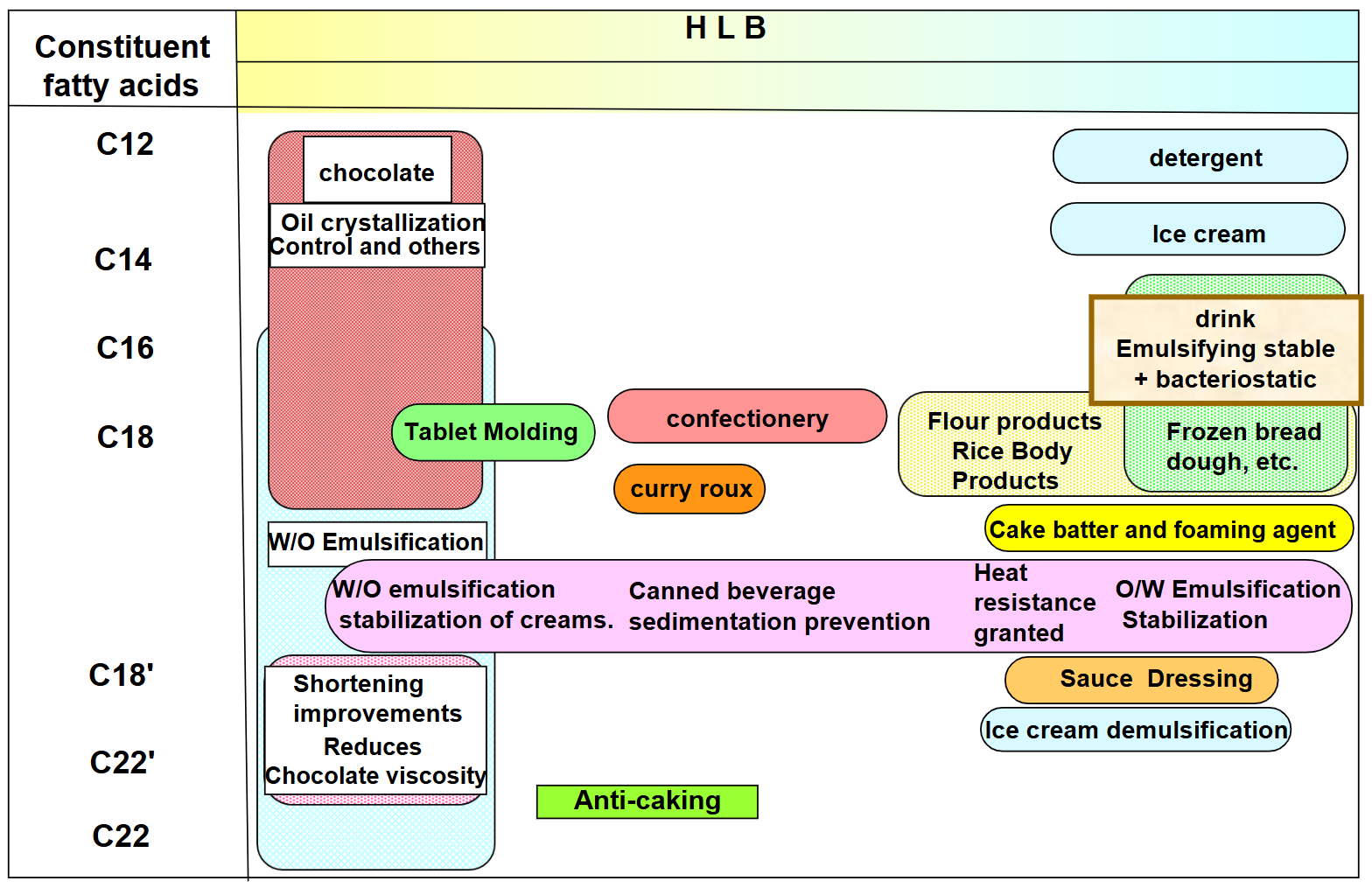

RYOTO™ Sugar Esters are compounds in which some or all of the eight hydroxyl groups of sucrose (sugar) are esterified with fatty acids derived from vegetable oils. By adjusting the esterification degree of Sugar Esters, a wide variety of grades with diverse properties can be produced. The HLB value varies depending on the type of fatty acid and the degree of esterification, which affects the functionality of the product.

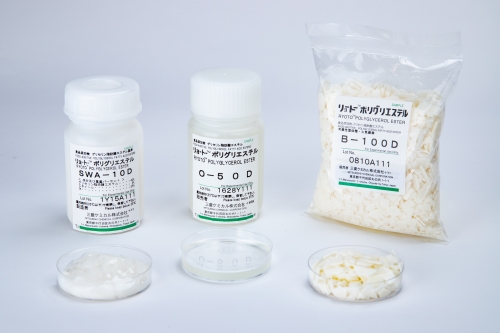

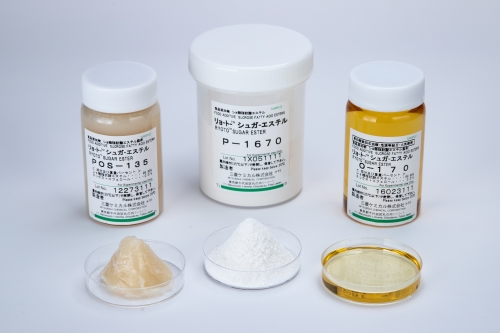

Product Lineup

RYOTO™ Sugar Esters are available in a wide range of grades based on the type of fatty acid (such as stearic acid, palmitic acid, and oleic acid) and their HLB values. The HLB value indicates the balance between hydrophilicity and lipophilicity and serves as a guide for selecting a grade appropriate for the application.

| Constituent Fatty Acids | HLB | ||||||||||

| <1 | 1 | 2 | 3 | 4 | 5 | 7 | 9 | 11 | 15 | 16 | |

| Lauric Acid C12 | L-195 | LWA-1695 | |||||||||

| Myristic Acid C14 | M-1695 | ||||||||||

| Palmitic Acid C16 | P-170 | P-1570 | P-1670 | ||||||||

| Stearic Acid C18 | S-070 | S-170 | S-270 | S-370 S-370F* S-370FU* | S-470 | S-570 | S-770 | S-970 | S-1170 | S-1570 | S-1670 |

| Oleic Acid C18' | O-170 | O-1570 | |||||||||

| Mixed Fatty Acids | POS-135 | ||||||||||

*Fine powder types available.

Lipophilic Sugar Esters(SOE)

- US FDA … CFR 172.869(Sucrose Oligoesters )

**S-070 and S-270 are not included. - JECFA … INS 473a

(Sucrose Oligoesters TypeⅠand Ⅱ) - EU EFSA … Not Permitted

Hydrophilic Sugar Esters(SEFA,SFAE)

- US FDA … CFR 172.859 (Sucrose Fatty Acid Esters)

GRN No.1123(Sucrose Fatty Acid Esters) - JECFA … INS 473 (Sucrose Ester of Fatty Acids)

- EU EFSA … E473 (Sucrose Ester of Fatty Acids)

Functions (Features) of Sugar Esters

RYOTO™ Sugar Esters reduce the interfacial tension between oil and water, thereby stabilizing emulsions. They form complexes with starch to prevent retrogradation and help maintain a soft texture of bakery products. They also control fat crystallization, suppressing bloom in chocolate. Additionally, they improve powder flowability and enhance lubricity during tableting. These multifunctional properties contribute to improvements of food quality and higher efficiency of manufacturing processes.

Application Examples

- For emulsion stability in RTD (ready-to-drink) beverages: S-570, S-1170, P-1570, P-1670, M-1695

- For bloom suppression in chocolate: POS-135, L-195

- For bread quality improvement: S-1170 to S-1670, P-1570, P-1670

- For tablet confectionery: S-370F, B-370F

| Additive Effects | Recommended Products | Recommended Dosage | |

| RTD (Bottled Beverages) | Main Functions: Emulsification and dispersion stabilization(Prevents creaming, aggregation, and sedimentation over time) | S-570, S-1170, P-1670, P-1570, M-1695 | 0.01 - 0.3% |

| Additional Function: Bacteriostatic effect against heat-resistant spore-forming bacteria | P-1670, P-1570, M-1695 | 0.01 - 0.3% | |

| Pancakes | Starch Gelatinization Control: Improved softness and increased volume | P-1670, S-1170 | 0.1 - 0.5% |

| Smooth mouthfeel (no stickiness or chewiness) | |||

| Starch Retrogradation Suppression: Maintains texture during storage (preserves softness) | |||

| Chocolate Confectionery | Bloom Retardation: Select appropriate sugar esters based on the type of fat used in chocolate | POS-135(CB, CBE) | 0.1 - 0.6% |

| L-195 (CBS) | 0.1 - 0.6% | ||

| Physical Property Control / Improvement of Manufacturing Efficiency: Reduces plastic viscosity without lowering yield value | ER-290, O-170 | 0.1 - 0.3% | |

| Thickening Suppression in Coating Chocolate: Suppresses thickening when overheated or when moisture is contaminated. | S-570, S-770 | 0.1 - 0.3% | |

| Tablet Candy / Supplements | Lubricity Enhancement / Improvement of Productivity: Prevents tableting failure during continuous production | B-370F, S-370F, S-370FU | 0.5 - 2.0% |

| Improves glossiness of tablet surface | |||

| Enhances powder flowability |

How to use Sugar Esters

Please use the standard method of addition that matches the HLB range of the sugar ester grades:

- Grades with HLB 0–2:Add Sugar Esters to heated fats and oils.In some cases, you may first disperse Sugar esters into a portion of the heated oil, then add the remaining oil.

Disperse in fats and oils and then heat to 70°C/158℉. It’s better to disperse Sugar Esters in a small amount of heated oil before adding it to the remaining oil.

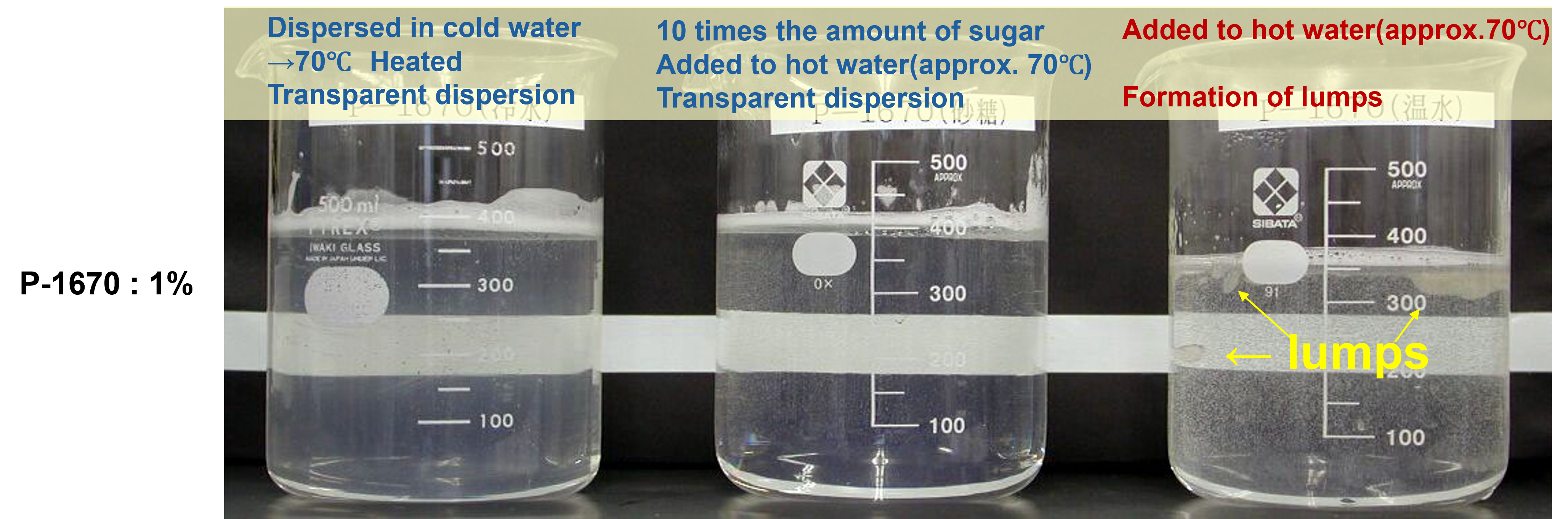

- Grades with HLB 4–9:Disperse Sugar esters in cold water, then heat to 60–80°C.Direct addition to hot water is also possible.

Disperse in water and then heat to 70°C/158℉. Direct addition to hot water is also possible.

- Grades with HLB 11–16:Disperse Sugar Esters in water at room temp. or below and then heat to 70°C/158℉.

There are two ways to disperse Sugar Esters into hot water directly :

- Premix with Sugar Esters and water-soluble powder (e.g., sugar) can be added directly into hot water.

- Add a pre-prepared high-concentration dispersion to hot water.

Note: Avoid adding sugar esters only to hot water because they may form lumps.

Dispersion in Oil and Water

| HLB Range of grades | Examples | Dispersion Medium | Dispersion Methods |

| 0 - 2 | S-170, S-270 | oil | ・Directly add to heated oil ・Disperse in a portion of heated oil, then add to the remaining oil |

| 4 - 9 | S-570, S-770 | water | ・Directly add to hot water ・Disperse in cold water, then heat |

| 11 - 16 | S-1170, P-1670 | water | ・Disperse in cold water, then heat ・Prepare as a high-concentration dispersion while stirring into several times amount of cold water, then add to a large volume of hot water ・First mixed with powdered ingredients such as sugar, then add to hot water |

Certifications of RYOTO™ Sugar Esters

RYOTO™ Sugar Esters were approved as food additives in Japan in 1959 and then many other countries/regions including the EU and United States. Their safety was also evaluated by international organizations, JECFA (Joint FAO/WHO Expert Committee on Food Additives).They are also certified for Halal and Kosher certifications.

Note: Users are required to check the latest regulations for each application.